SSL-100

Our SSL-100 vertical sleeve labeler is a performance-driven label applicator with a small footprint able to label at up to 100 CPM.

Our SSL-100 is a state of the art machine sharing the same construction and touch control interface of our other machines.

SSL-100L Large Format Sleeve Labeler

Sleeve Seal’s new large format labeler offers XXL container capacity.

Automated, oversized labeling just got easy. Our new SSL-100L labeler handles containers up to 8.5” in diameter with extra long label lengths. Sleeve Seal’s “all day long, all day strong” reliability has been applied to an extra strength drive train to accommodate your large format packaging requirements.

FS1 Sleeve Labeler

The Sleeve Seal FS1 is a new concept in sleeve labelers.

The FS1 MKII is a newer model that has become very popular due to its performance over a wide range of formats and speeds.

FS2 Sleeve Labeler

The Sleeve Seal FS2 sleeve labeler.

With speeds up to 375CPM, the FS2 is a precision machine with the durability that has made Sleeve Seal an industry leader.

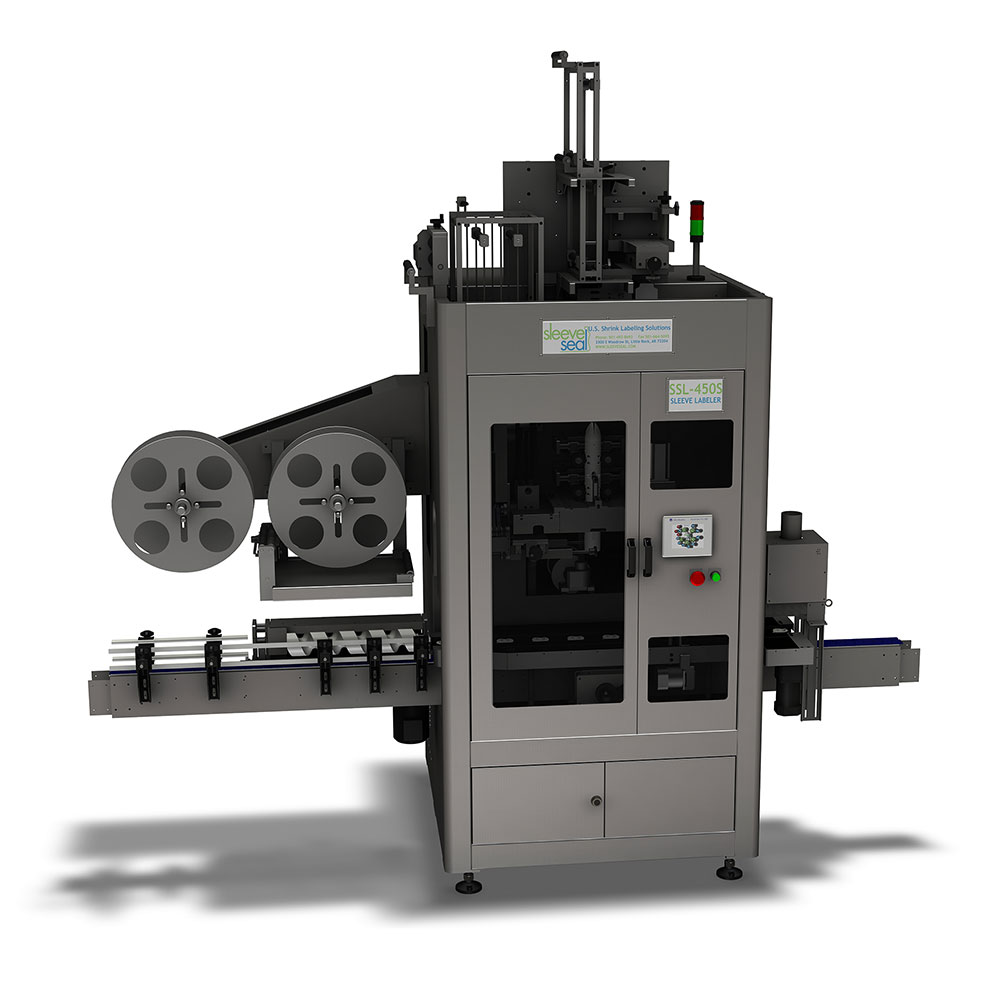

SSL-450

Compare the SSL-450 to a small block V8 American hot rod – speed & dependability in a smaller package.

Sleeve Seal has engineered the SSL-450 series of machines to be hard running, robust machines that can stand alone with the two-reel capacity of the SSL-450S or can be mated to high capacity label accumulation systems for high volume with the SSL-450R.

SSL-800

The SSL-800 runs at “push you back in your seat” speeds.

Sleeve Seal’s single head vertical sleeve labelers have been engineered to hit high speeds applying long cut lengths.

SSL-800i

The SSL-800i is our fastest intelligent shrink sleeve labeling machine.

The intelligent controls included in the SSL-800i give you state-of-the-art flexibility in sleeve labeling, the SSL-800i is a dependable, self-contained sleeve labeler.

SSL-1600

The SSL-1600 is our new vertical sleeve labeler speed champ.

The two-lane, dual synchronized head system provides unique speeds and can employ two independent functions for each labeling head.